版权所有 © 2018 山东中灿 ICP备案号:鲁ICP备16001552号-1 网站建设:中企动力 济南二分

ABOUT US

Tel: 0086-538-6315517

Fax: 0086-538-6315510

Phone:0086-15588577955

Adress:Hi-Tech Development Zone,

Feicheng,Taian,Shandong ,China.

E-mail:ella@zhongcansteel.com

PRODUCTS

websites

0086-538-6315517

Service Hotline

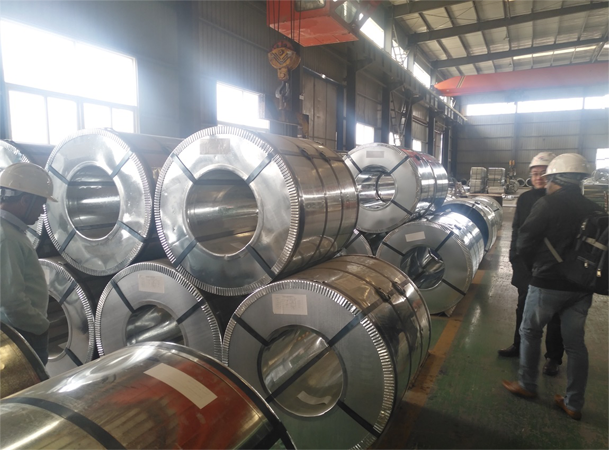

Development History of Galvanized Steel Coil

Hot dip galvanizing is also called hot dip galvanizing and hot dip galvanizing: it is an effective metal anti-corrosion method, mainly used on metal structures and facilities in various industries. It is a process technology that steel, stainless steel, cast iron and other metals are immersed in molten liquid metal or alloy to obtain coating. It is a widely used steel surface treatment method with excellent performance and price in the world today. Hot dip galvanized products play an inestimable and irreplaceable role in reducing corrosion and prolonging life of steel, saving energy and materials. At the same time, coated steel is also a short-term product with high added value supported and prioritized by the state.

Production process

The production and processing of galvanized steel coils can be divided into three steps: first, the whole coil of strip steel shall be pickled to remove rust and dirt, so as to make the surface of galvanized steel strip bright and clean; After pickling, it is cleaned in ammonium chloride or zinc chloride aqueous solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot dip tank for galvanizing; Warehousing and packaging can be carried out after the galvanizing process is completed.

History of Hot Dip Galvanizing

Hot dip galvanizing was invented in the middle of the 18th century. It was developed from the hot tin plating process and has entered the fourth century. Up to now, hot galvanizing is still a more common and effective process measure in steel corrosion prevention methods.

In 1742, Dr. Ma Luoying carried out a pioneering experiment on the hot-dip galvanizing of steel and read it out at the French Royal Academy.

In 1837, Sorrill of France applied for a patent for hot galvanizing and proposed the idea of using galvanic cell method to protect steel, that is, the process of galvanizing and rust prevention on the iron surface. In the same year, Crawford of the United Kingdom applied for a patent for zinc plating with ammonium chloride as the solvent. This method has been followed up through many improvements.

In 1931, Senjimir, a particularly outstanding engineer in the modern metallurgical industry, built the world's first hydrogen reduction continuous hot-dip galvanizing production line for strip steel in Poland. The method was patented in the United States and the industrial hot-dip galvanizing production line named after Senjimir was built in Maubeuge Steel Plant in the United States and France in 1936-1937, creating a new era of continuous, high-speed and high-quality hot-dip galvanizing for strip steel.

In the 1950s and 1960s, the United States, Japan, Britain, Germany, France, Canada and other countries successively produced aluminized steel plates.

In the early 1970s, Bethlehem Iron and Steel Company invented the aluminum zinc silicon coating material with the trade name Galvalume, and its corrosion resistance is 2-6 times that of pure zinc coating.

In the 1980s, Europe, America, Australia and other places rapidly promoted hot galvanizing nickel alloy, and its process was named Technigalva At present, Zn Ni Si Bi has been developed on this basis, which can obviously inhibit the Sanderling reaction of silicon containing steel during hot plating.

In the 1990s, Nishin Steel Co., Ltd. of Japan developed a zinc aluminum magnesium coating material with the trade name ZAM. Its corrosion resistance is 18 times that of traditional zinc coating, and it is called the fourth generation high corrosion resistance coating material.

Product features

·It has better corrosion resistance and longer service life than ordinary cold-rolled sheet;

·Good tightness and weldability;

·A variety of surfaces can be selected: large zinc flakes, small zinc flakes, no flowers;

·Various surface treatments, such as passivation, oiling, finishing, environmental protection, etc;

Product use

Hot dip galvanized products are widely used in many fields. Its advantages lie in its long anti-corrosion life and wide adaptability to the environment. It has always been a popular anti-corrosion treatment method. It is widely used in electric power tower, communication tower, railway, highway protection, street light pole, marine components, building steel structure components, substation ancillary facilities, light industry, etc.