版权所有 © 2018 山东中灿 ICP备案号:鲁ICP备16001552号-1 网站建设:中企动力 济南二分

ABOUT US

Tel: 0086-538-6315517

Fax: 0086-538-6315510

Phone:0086-15588577955

Adress:Hi-Tech Development Zone,

Feicheng,Taian,Shandong ,China.

E-mail:ella@zhongcansteel.com

PRODUCTS

websites

0086-538-6315517

Service Hotline

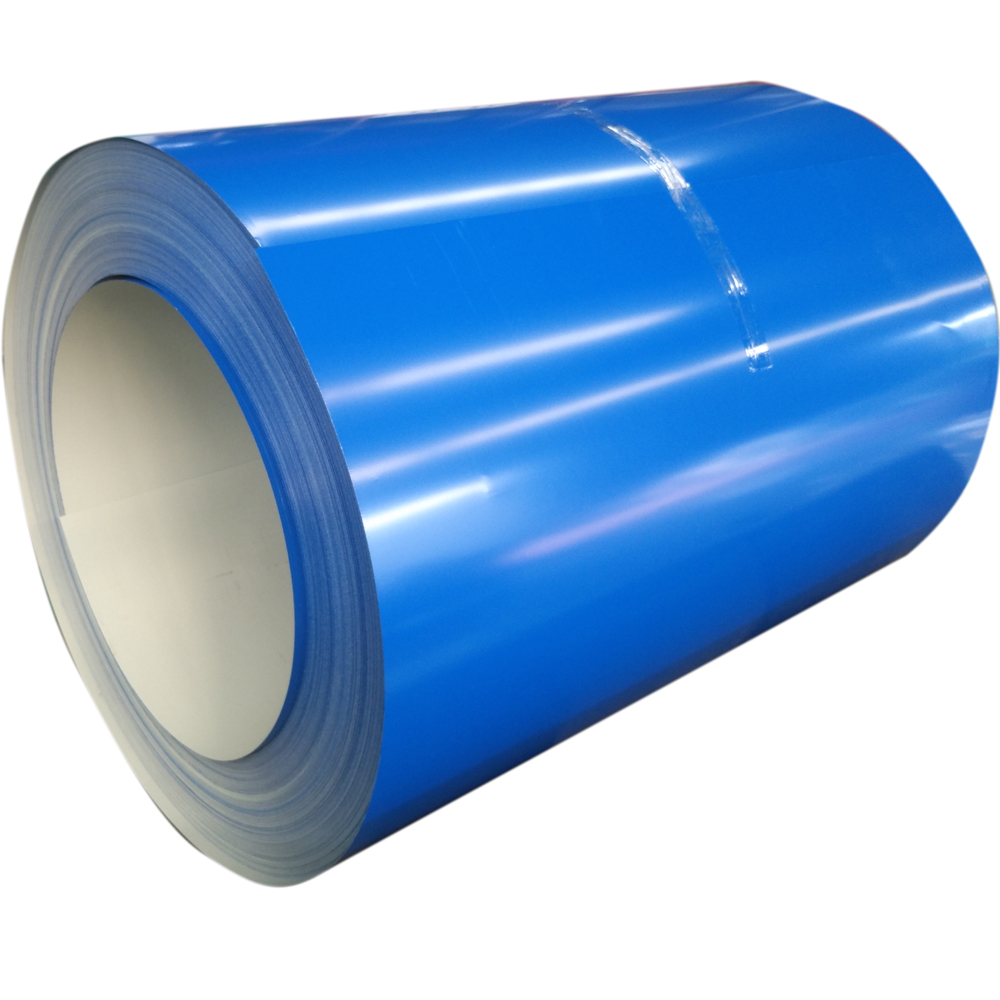

Instructions for painted board

I. matters needing attention in material selection of color coated board:

Color coated board according to the final use of the use of the material selection, to meet the use of the appropriate price.It mainly considers the external atmospheric environment contacted by the color coated board, and the relatively closed internal environment, that is, rural atmosphere, urban atmosphere, industrial atmosphere, ocean atmosphere, and at the same time, considering acid, alkali, salt, humidity, light, ventilation and other specific specific to the actual use of the specific environment, can be judged separately.

Ii. Precautions for storage, transportation and loading and unloading of color coated boards:

1, color coating products stored in a dry, ventilated environment, should be far away from acid, alkali, salt and other organic solvents and corrosive media;

2, in the process of transportation, loading and unloading to prevent rain, snow, fog water invasion, paint film damage and pollution, knock, extrusion surface corrosion;

3. The product volume shall be transported according to the state of delivery, and the original package shall not be dismantled at will.

Iii. Processing and installation of color coated board

1. Follow the principle of choosing the same manufacturer and batch of products for the same project according to the design requirements to avoid the influence of color differences on the appearance;

2. If the product is found to have abnormal appearance and quality after receiving the product, stop using it and contact the supplier immediately.

3. Avoid low-temperature processing (above 7℃) of color coated board, choose suitable mechanical processing color coated board, check product board surface, adhesion and other quality indicators in the process of processing and use, if there is a quality problem, find out the cause and take measures to continue processing and use;

4, color coated plate in the processing, installation and application of the link to avoid cutting high temperature metal powder adhesion, color tile profile layer between layers of sliding, collision, the application of mechanical tools, hard sole shoe tread and other damage protective coating products, fixed bolts choose waterproof, anti-corrosion material seal;If the surface damage occurs in the process of processing and installation, the special repair coating should be used to repair in time to ensure the service life of the color coating plate;

5. After the installation of colored tiles, the board surface and incision should be kept clean and away from cement, acid, alkali, salt and other corrosive media;

6. In the process of transportation, storage, processing and installation, it is contraindicated to expose to direct sunlight and other ultraviolet lamps for a long time;

7. As the color coated board for the roof, the installation slope is recommended to be no less than 10 degrees.After installing the color board, the board surface should be kept clean to ensure the service life of the color board;

Iv. Security precautions:

The company's color coated products with anti-counterfeiting spray code on the reverse side, at the same time the product with the quality certificate, if you have any questions, you can contact us at any time.

The color coating products of the company are made of high-quality hot-plated (aluminum) zinc substrates processed by hot-rolled steel mills in first-tier state-owned steel mills in China, and are made of world-renowned akzo Nobel, shell and PPG coating manufacturers. The coating types include ordinary polyester (PE), silicon-modified polyester (SMP), high-durability polyester (HDP), polyvinylidene fluoride (PVDF), etc.Focus on creating "high-quality, refined" high corrosion resistance •Pro series products, etc., while producing anti-static board, self-cleaning board, purification board, printing board, suede board, screen board and other functional color coating products, to meet the needs of different users, can be customized for customers.

The company caitu products rely on the company's advanced management and technology research and development, the real test for support, excellent processing performance, durability and rich variety of color, and can according to user requirements to provide individualized small technical services department of product research and development and engineering use, widely used in construction, household appliances, decoration, specific environment, etc.