版权所有 © 2018 山东中灿 ICP备案号:鲁ICP备16001552号-1 网站建设:中企动力 济南二分

ABOUT US

Tel: 0086-538-6315517

Fax: 0086-538-6315510

Phone:0086-15588577955

Adress:Hi-Tech Development Zone,

Feicheng,Taian,Shandong ,China.

E-mail:ella@zhongcansteel.com

PRODUCTS

websites

0086-538-6315517

Service Hotline

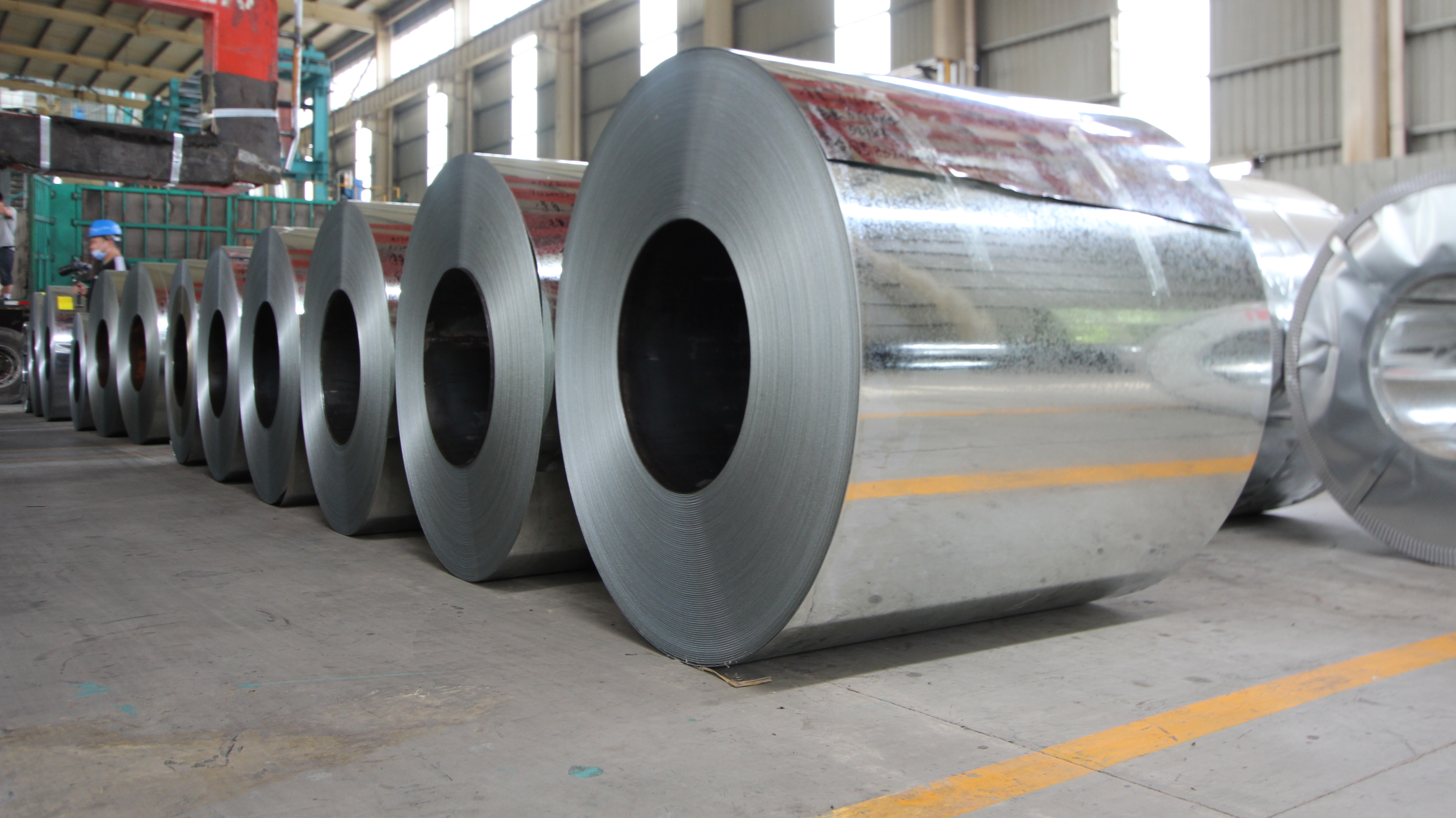

Practical Application of Galvanized Steel Coil

Galvanized products can be seen everywhere in our lives. All steel processing products with corrosion resistance requirements, including corrugated plates used as building materials, automobile sheet metal used as car facades, refrigerators that are opened every day, as well as high-grade computer server shells, furniture, color baseplates, slide rails, air ducts, etc., may be processed by using hot-dip galvanized steel coils of Sinosteel.

For example, the shells of some advanced computers and servers will not be painted, but will be directly bare with galvanized steel sheets. For these manufacturers, they will require a thin zinc coating to maintain the beautiful surface quality of products. Relatively speaking, manufacturers of building materials wave plates have low requirements on the surface quality of steel coils. Considering that wave plates may be erected in places with poor environment, they will use thicker zinc layers to manufacture products with high corrosion resistance.

Due to the different thickness of galvanizing die required by different customers, how to accurately control the thickness of zinc layer has become a major challenge for Zhongcan Hot Dip Galvanizing Plant.

Different products have different galvanized film thicknesses. If too much zinc is plated, which is higher than the thickness required by customers, zinc is one of the high cost raw materials, which will cause cost waste; If the zinc coating does not meet the product specification, it will lead to the customer's inability to use or subsequent problems in processing, resulting in customer complaints about quality.

If the hot-dip galvanizing method is explained in one sentence, it is to put the steel coil into the zinc bath to make both sides of the coil be coated with zinc liquid, so that a thin layer of zinc can be attached to the surface of the steel sheet, which can resist corrosion. However, in fact, to produce several tons of hot-dip galvanized steel coils, it requires a series of complex treatment processes, successively entering the feeding area, the annealing area, the galvanizing area, the tempering and leveling area, the coating area, the inspection area, and the discharge area to complete the hot-dip galvanizing work.