PRODUCT CENTER

Professional Scientific Research Team, Strictly Control The Quality On Each Steps Of Production. Including Inspection On Raw Materials Entry, Product's Color

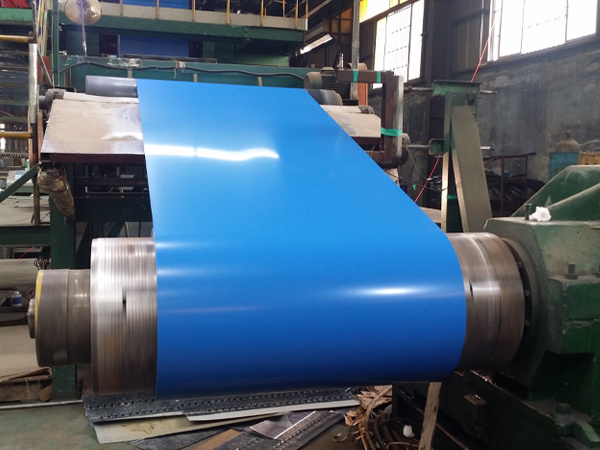

PPGI coil is a highly popular material used for roofing sheets, wall panels, furniture, home appliances, automobile components, and more. It keeps the strength of galvanized steel, while its organic coating offers various colors and an attractive appearance.

PPGL steel is a durable, colorful, and economical building material. It is the abbreviation for pre-painted galvalume steel, which is with Al-Zn coated steel sheet substrate. Then the Al-Zn coated steel is painted continuously in coil form.

Galvanized steel coils are steel sheets or strips that have been zinc-coated to keep them from corroding. Galvanization includes immersing steel coils in molten zinc baths or imparting a zinc coating via a continuous hot-dip galvanizing process.

Galvalume steel coil is carbon steel coated with an aluminum-zinc alloy using a continuous hot-dipped process combining the corrosion protection and high-temperature resistance of aluminum with the formability and galvanic protection of zinc.

Type 316L stainless steel in a molybdenum bearing austenitic. It is more resistant to general corrosion and pitting than conventional nickel chromium stainless steels such as 302-304. It has the following characteristics:Higher creep resistance,Excellent formability,Rupture and tensile strength at high temperatures,Corrosion and pitting resistance.

Pattern printed steel is a kind of color coated steel product available in various patterns. Due to its pretty appearance, convenience, and excellent corrosion resistance, it is widely used in home appliances, furniture, and building decoration in recent years.

Electro-Galvanized Coil EG Coil

Electro-galvanized steel is carbon steel with a corrosion-resistant zinc coating applied to one or both of its sides by electro-deposition. The continuous electrolytic coating process covers the steel surface with an exceptionally uniform thickness, which can enhance forming and joining operations.

1050 Aluminum is a commercially pure aluminum alloy that is known for its excellent corrosion resistance, high thermal conductivity, and good workability. It is commonly used in various industries such as electronics, chemical equipment, and signage.

1060 aluminum is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1060 aluminum has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.

Aluminium 1070 alloy is a wrought alloy type with good corrosion resistance. It is an excellent brazing alloy.</br> Aluminium 1070 alloy is chiefly used in the following areas:General industrial components,Building and construction,Transport,Electrical material,PS plates,Strips for ornaments,Communication cables,Refrigerator and freezer cabinets,For joining two pieces of aluminium / aluminum.

Aluminum 1100 is one of the most widely used alloys, with excellent forming properties, especially in the fully soft, annealed temper. It may be suitable for applications that require bending, spinning, drawing, stamping and roll forming.</br> Aluminum 1100 alloy is widely used in fin stock, heat exchanger fins, spun hollowware, dials and name plates, decorative parts, giftware, cooking utensils, rivets and reflectors, and in sheet metal work.

Aluminum 3003 alloy has moderate strength and good corrosion resistance. The strength of this alloy can be increased by cold working.</br> Aluminium 3003 alloy is used in ductwork, chemical equipment, and general sheet metal work. It is also used in manufacturing the following items:Cooking utensils,Builder's hardware,Pressure vessels,Ice cube trays,Eyelet stock,Awning slats,Gas lines,Garage doors,Refrigerator panels,Heat exchangers,Gasoline tanks,Storage tanks,Drawn and spun parts.

3A21 aluminum is the most widely used type of anti-rust aluminum. Its strength is not high (slightly higher than industrial pure aluminum). 3A21 aluminum can not be strengthened by heat treatment. So cold processing method is adopted to improve its mechanical properties.

Aluminum 5052 alloy is a non-heat treatable alloy with good corrosion resistance, especially to salt water.</br> Aluminum 5052 alloy is used in the manufacture of the following products:Milk crates,Hydraulic tubes,Appliances,Kitchen cabinets,Small boats home freezers,Aircraft tube,Fencing.

Aluminum 5005 alloy is a non-heat treatable alloy with small amount of magnesium content. It has excellent corrosion resistance and weldability characteristics. </br> Aluminum 5005 alloy is widely used in the manufacture of the following products:Small boats,Appliances,Utensils,Gas lines,Refrigerator panels.

The 5A05 aluminum is an Al-Mg rust-proof aluminum alloy, which cannot be heattreated and the colddeformation of the alloy can improve the strength. The plasticity in the annealed state is high, and the plasticity in the semi-cold hardening state is acceptable. The alloy has good corrosion resistance and good weldability, and is suitable for spot weldingatomic hydrogen welding, gas welding, and argon arc welding. its machinability, semi-cold hardening state is still good.</br> Application areas: armor plates, high-strength structural parts, ship sheet metal parts, fuel tanks, etc.

Aluminium 5083 is known for exceptional performance in extreme environments. Aluminium 5083 is highly resistant to attack by both seawater and industrial chemical environments.</br> Aluminium 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65°C.</br> Aluminium 5083 is used in:Shipbuilding,Rail cars,Vehicle bodies,Tip truck bodies,Mine skips and cages,Pressure vessels.

Aluminum 6061 alloy can be easily formed and worked in the annealed condition.</br> Aluminum 6061 alloy has excellent weldability. Thinner sections can be welded using the gas tungsten arc welding technique. Heavier sections can be welded using the gas metal arc welding technique.</br> Aluminum 6061 alloy is used in the following applications:Truck and marine components,Furniture,General structural and high-pressure applications,Pipelines,Heavy-duty structures,Railroad cars,Tank fittings.

201/201LN stainless steel is an austenitic steel. Its primary alloying elements are chromium, nickel, and magnesium. It shows excellent toughness at lower temperatures and is purposed across industries for use in appliances, restaurant equipment, sinks, automotive trim, and more.

202 stainless steel strip has good high temperature resistance.</br>Applications: Architectural decoration, municipal engineering, highway guardrail, hotel facilities, shopping malls, glass handrails, public facilities and other places.</br>Workability: Cut, Form and Machine with proper equipmen.

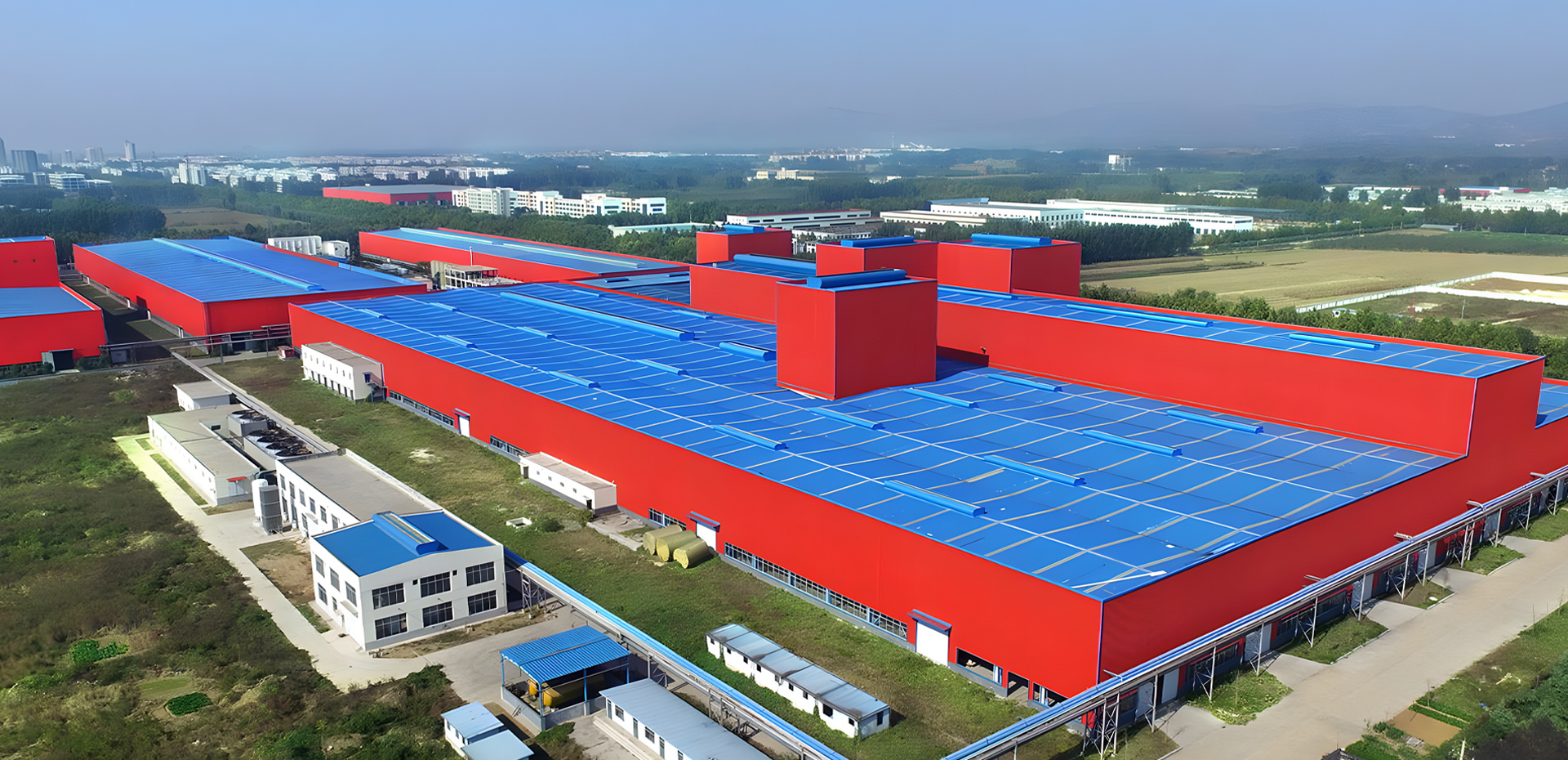

Shandong ZhongCansteel New Material Co.,LTD

Shandong ZhongCansteel New Material Co.,LTD. Is a modern integrated production enterprise which incorporates the processing & manufacturing of Cold-rolled Steel, Galvanized Steel, Galvalume Steel, and Prepainted Steel, sales and logistics.The total investment of the project is 2.6 billion RMB, covering an area of 128.5 acres, with an annual capacity of 1.5 million tons.

Our Products Sell Pretty Well Not Only In Domestic Market, But Also Prevails In Europe, Such As Southeast Asia, Russia, Ukraine, The United States, Canada, Brazil, Colombia And Other Countries And Regions, Which Has Earned The Customers Trust & Compliment And Successfully Transitioned From Home To Abroad.

Production Experience

Active Employees

Square Meter

Advanced Production Equipment

Cold rolling steel production line with annual output of 300,000 tons,Which adopts the most advanced cold rolling equipments and automatic thickness control system in China.

Strict Quality Testing

Zhongcansteel introduces the advanced testing equipments and builds up a professional scientific research team,strictly control the quality on each steps of production...

Strict Production Attitude

including inspection on raw materials entry,product's color analysis during production,-bend test, impact test, salt-spray test, tensile test and packaging testing on exported products...

Good Customer Reputation

In the 21st century, zhongcansteel is holding fast to the opportunities, and with a firm belief that " basing in China then marching towards the world" , constantly seeking innovations and developments.

BLOG CENTER

Zhongcansteel is based on integrity. Ensuring the quality of the products and prompt delivery and satisfying after-sales service will reassure our customers, we will be your trustworthy trading partner!!